Trending Popular

Categories Popular

How Has Dares of Eternity Evolved Over Time in Destiny 2

In this blog post, we’ll explore the evolution of Dares of Eternity, one of Destiny 2’s...

A Guide to Iron Banner Rewards in Destiny 2

Latest News

Featured Popular

How to Easily Frame Your Own Canvas Painting

The first cave paintings in history were made on rock, but as textiles like canvas and other...

16 Cute Matching Couple T-Shirt Ideas [ With Link to Buy]

10 Insanely Epic Sushi and Sashimi Knives Reviews 2021

Must Read

The Best Magnetic Knife Holder...

Top 9 Coolest Motorcycle Helmets...

9+ Unique and Coolest USB...

9 Best Gun Concealment Furniture...

10 of the Most Coolest...

More Stories Popular

Prophecy Dungeon Loot: Location, Mechanics, and Strategies

Have you ever wondered what secrets lie within the mysterious Prophecy dungeon? As a fellow...

Grasp of Avarice: Loot Guide & Dungeon Tips in Destiny 2

Have you ever wondered about the secrets hidden within the Grasp of Avarice dungeon? As a fellow...

How Has Dares of Eternity Evolved Over Time in Destiny 2

In this blog post, we’ll explore the evolution of Dares of Eternity, one of Destiny 2’s...

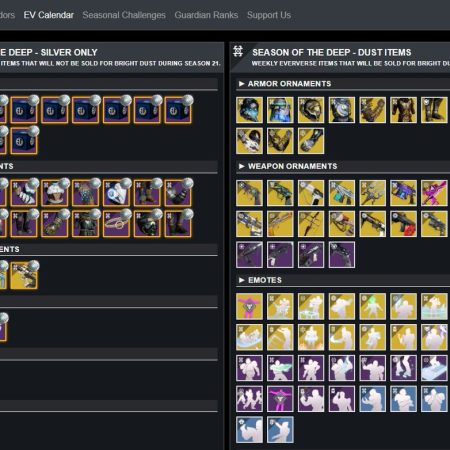

10 Must-Have Eververse Calendar Items in Destiny 2

Are you tired of missing out on the best Eververse items in Destiny 2? With so many options...

Dares of Eternity Loot Pool in Destiny 2: A Player’s Guide

Are you a Destiny 2 player looking to maximize your loot from the Dares of Eternity activity? This...

A Guide to The Root of Nightmares Loot Table

Are you ready to uncover the mysteries that lie at the very heart of the Black Garden? The Root of...

Inside the Eververse Calendar: Monthly Surprises Revealed

Have you ever found yourself scrambling at the end of the season, trying to snag that perfect...

![16 Cute Matching Couple T-Shirt Ideas [ With Link to Buy]](https://cubbyhomedesign.com/wp-content/uploads/2021/03/16-Cute-Matching-Couple-T-Shirt-Ideas-With-Link-to-Buy-450x350.jpeg)